Ever wondered how those intricate metal shapes in your gadgets are carved out? Let me take you through a journey into the world of carbide burrs – the unsung heroes of metalwork. It’s a tale of precision, durability, and tiny tools with a big impact.

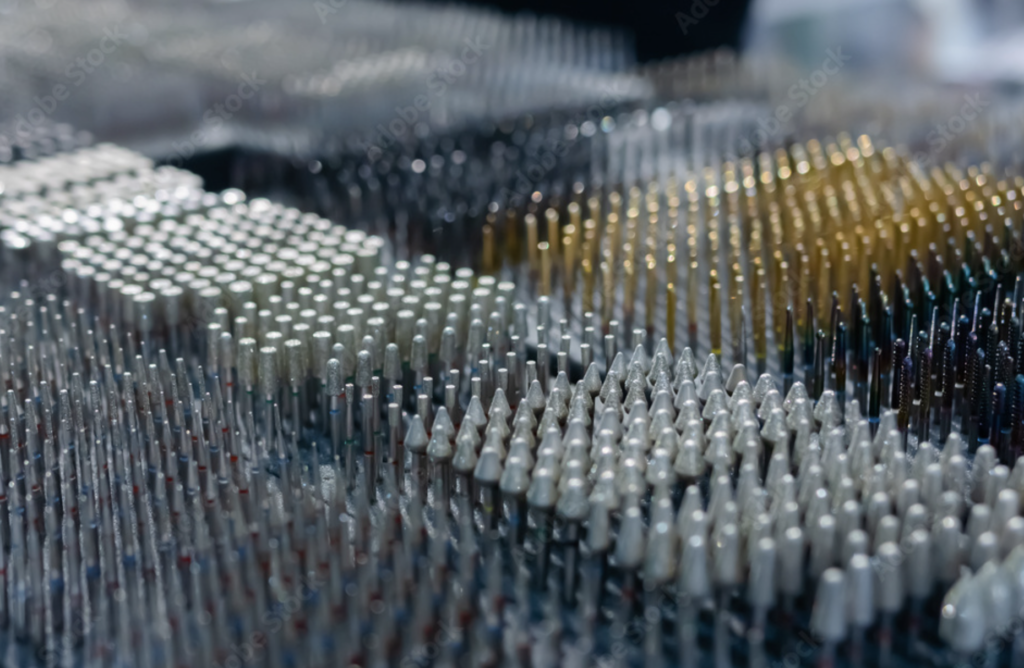

Carbide burrs(also known as Rotary Burrs) are small cutting tools used extensively for shaping, carving, and removing material from various types of metal. Made from tungsten carbide, a material prized for its stiffness and hardness, these burrs outperform steel counterparts in speed, precision, and longevity. Their usage spans industries, simplifying complex tasks in manufacturing, construction, and automotive applications.

In our factory, you’ll see carbide burrs in action, dancing on metal surfaces, crafting perfection. It’s a symphony of precision where every note matters, and every movement is calculated.

Why Are Tungsten Carbide Burrs So Special?

Now, when I talk about carbide burrs, I’m not referring to your everyday, run-of-the-mill tools. These are the Ferraris of the tool world. Why? Because tungsten carbide is about as tough as it gets.

Imagine a material that can withstand high temperatures, resist abrasion, and laugh in the face of wear and tear. That’s tungsten carbide for you. And when we shape it into burrs, magic happens – metal yields to our designs with both grace and precision.

What Can You Achieve with These Mighty Tools?

Let’s say you’re into creating detailed sculptures or need to fine-tune a precision part for an engine. With a set of our burrs, you’re not just working metal; you’re an artist, and metal is your canvas.

The beauty of these tools lies in their versatility. From carving to engraving to hollowing out, there’s a burr for every twist and turn your project takes. And they come in various shapes and sizes – think of them as your metalworking paintbrushes.

How Does a Carbide Burr Fit into the Manufacturing Process?

In our world at ShenTools, carbide burrs are the bread and butter of manufacturing. Without them, achieving the detailed work required in high-stakes industries would be like trying to paint the Mona Lisa with a broom – possible, but not pretty.

We equip businesses with the tools to do the delicate dance of metalwork, ensuring that every cut is as precise as a surgeon’s incision. This is not just about shaving off metal; it’s about shaping the future, one burr at a time.

Are Carbide Burrs Only for the Big Players?

Think carbide burrs are only for the big leagues? Think again. Whether you’re a hobbyist tinkering in your garage or a small shop crafting bespoke pieces, these tools scale to fit your needs.

And here’s a little secret – size doesn’t matter. It’s the skill and the quality of the tool that counts. With our burrs, even the smallest player can punch well above their weight.

How Do You Choose the Right Carbide Burr?

Choosing the right carbide burr is like selecting the perfect wine – it needs to complement the meal, or in this case, the material and the job. There’s a shape for every task, and the trick is knowing which one to pick.

We at ShenTools guide our clients through this selection process. Consider us the sommeliers of carbide burrs, offering you the perfect tool pairing for your metalworking endeavors.

Conclusion

So, there you have it – a glimpse into the world of carbide burrs through the eyes of someone who lives and breathes metalwork. They may be small, but they are mighty, and at ShenTools, we wield them like knights of old wielded swords – with skill, honor, and a dash of flair.

That’s the end of our metal saga. Now, go forth and create with the confidence that you’ve got the best tools in the business backing you up. And remember, with great burrs comes great responsibility.