Shen Tools is a manufacturer of carbide burrs. Our carbide burrs factory in china supply all models and sizes. Used in Manufacturing, Automotive, Aerospace, Construction, Metalwork and other industries.

Carbide Burrs is a tool used for cutting, shaping, grinding, and removing sharp edges, burrs, and excess material (deburring). Also called Rotary Burrs.

This article discusses popular topics on carbide burrs, including their uses, application fields, usage methods, matching tools, working principles, buying considerations, as well as the different classifications of carbide burrs.

Carbide burrs are primarily used for material removal, grinding, deburring, shaping, and providing a finished surface on a host of materials including metal, plastic, wood, and ceramic.

Carbide burrs perform cutting work by rotating at high speeds. In layman’s terms, it is fixed by some auxiliary tools (such as pneumatic tools), and the surface is polished after high-speed operation. Examples include metalworking, woodworking, and engraving, for tasks such as shaping, cutting, and removing material.

Material: Carbide burrs are usually made from tungsten carbide, a very hard material that can withstand high temperatures.

Mechanism: When mounted on a rotary tool, the burr rotates at a high speed. This allows the cutting edges on the burr to chip away material from the workpiece.

Compatibility: Different shapes and sizes are designed for specific tasks, such as deburring, grinding, or shaping materials like metal, wood, or plastic.

Auxiliary Tools

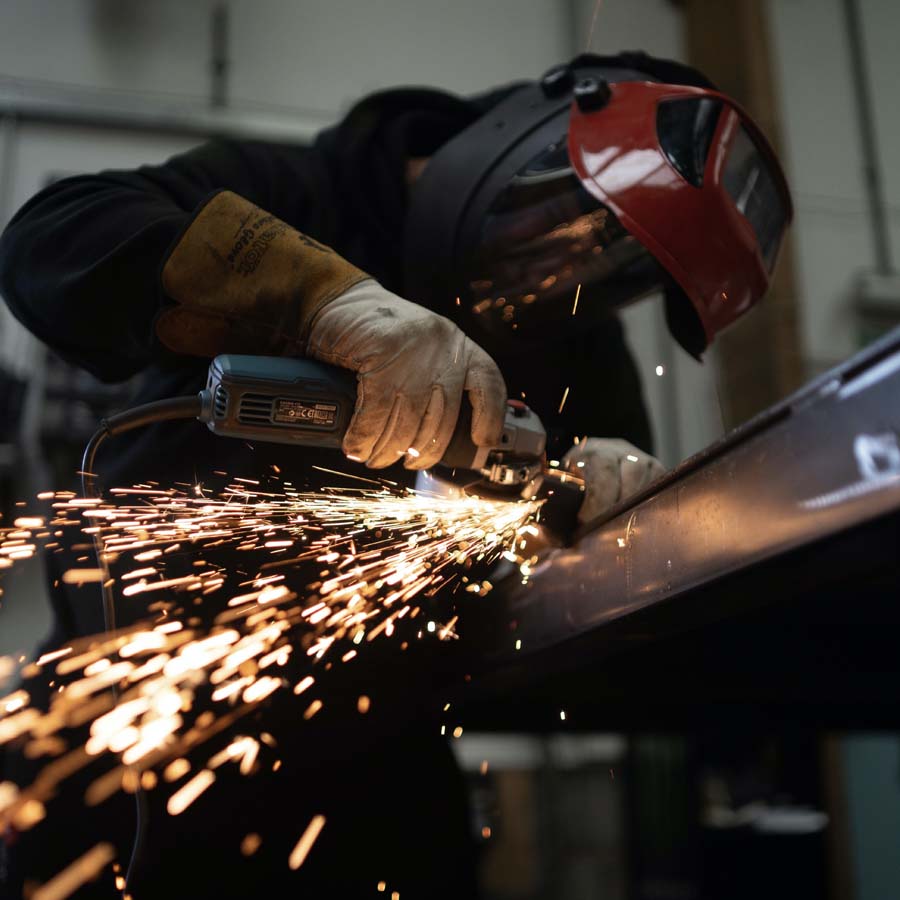

Die Grinder: This is the most common tool used to power carbide burrs. It’s a handheld power tool used for grinding, sanding, honing, or machining various materials.

CNC Machines: For industrial applications, carbide burrs are often mounted on CNC machines for precise automated operations.

Safety Gear: This includes gloves, safety goggles, and other PPE to ensure safety while using carbide burrs.

Workbench and Clamp: To securely hold the workpiece.

Safety First: Always wear appropriate safety gear, including safety goggles and gloves.

Work Area: Make sure your workspace is clean and well-lit.

Inspect the Burr: Before use, ensure that the carbide burr has no visible damage and is appropriate for your material and application.

Mount the Burr: Insert the carbide burr into the die grinder or CNC machine and tighten securely.

Secure the Workpiece: Use a workbench and clamps to securely hold the material you are working on.

Test Run: Power up the tool without it touching any material to ensure the burr is securely mounted.

Speed Settings: Adjust the rotary tool to the desired RPM (Revolutions Per Minute). Too high or too low can either damage the material or the tool.

Apply Lubricant: If needed, apply cutting oil or another appropriate lubricant to the material.

Tool Operation: Gently apply the rotating burr to the workpiece. Use steady, even pressure and let the tool do the work. Don’t force it into the material.

Material Removal: Move the tool across the workpiece, observing how material is removed and making adjustments as needed.

Cool Down: Allow the burr and workpiece to cool down periodically to avoid overheating.

Inspection: After you’ve achieved the desired results, switch off the rotary tool and inspect your work for any issues.

Clean Up: Clean the burr and the workpiece. Store the burr in a safe location for future use.

Tool Maintenance: Regularly inspect and clean your die grinder or CNC machine according to the manufacturer’s guidelines.

Certainly. The advent of carbide burrs arose from the need for a more durable, efficient, and precise cutting tool compared to traditional high-speed steel (HSS) cutters and stone abrasives.

While HSS cutters have their merits, they wear down quickly and need frequent replacement, leading to downtime in operations. Stone abrasives, on the other hand, can be imprecise and unsuitable for detailed work.

Carbide burrs offer a superior alternative by providing exceptional hardness and heat resistance, allowing them to maintain a sharp edge for much longer.

This results in less frequent tool changes, increased productivity, and a more refined finish. Their versatility makes them suitable for a broad range of materials and applications, from metal and wood to ceramics and plastics.

Hence, carbide burrs are not just an improvement but rather a paradigm shift in material processing, combining longevity with unparalleled accuracy. They offer industries a tool that is both cost-effective and capable of meeting high-quality standards.

Carbide burrs are the most durable, efficient, and precise cutting tools available. However, there are many types of carbide burrs and various models.

Whether you’re deburring, shaping, or grinding, each task may require a different shape and size of burr.

First we need to determine the parameters of burr according to your application.

Material Type: Different carbide burrs are suited for different materials—steel, aluminum, wood, etc. Make sure you choose a burr designed for the material you’ll be working on.

Burr Specifications& Shape: Burrs come in various shapes like cylindrical, pointed, ball-shaped, etc. Each shape has its specific application.

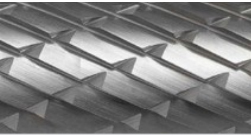

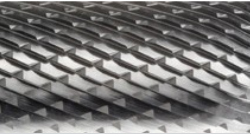

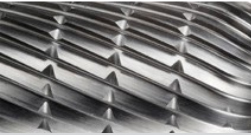

Cutting Edge: Some burrs have a single cut, while others are double cut or diamond cut. Each has its own benefits in terms of material removal and finish.

Diameter and Length: Make sure to choose the diameter and length that fit your machine and are appropriate for your work.

Shank Size: Ensure that the shank size of the burr fits the collet or chuck of your rotary tool or die grinder.

Customer Reviews: Check reviews to see if the burr has worked well for others in similar applications.

Compatibility and Safety

Tool Compatibility: Make sure the burr is compatible with the rotary tool or die grinder you plan to use.

Speed Rating: Check the maximum RPM (Revolutions Per Minute) rating on the carbide burr to ensure it is compatible with your rotary tool’s speed.

Cost and Budget

Cost-effectiveness: While it may be tempting to go for the cheapest option, remember that you often get what you pay for.

Bulk Purchase: If you have a large-scale project, see if there are bulk discounts available.

After-Sale Services

Warranty: Check if the product comes with a warranty and what it covers.

Customer Support: Ensure that the seller offers customer support in case you have questions or issues post-purchase.

Different tooth shapes are suitable for different scenarios. For example, some are suitable for flat surface grinding and some are suitable for interior grinding.

CYLINDRICAL BURRS WITH FLAT END

CYLINDRICAL BURRS WITH END CUT

CYLINDRICAL BURRS WITH RADIUS END

SPHERICAL/ BALL BURRS

OVAL SHAPE

TREE SHAPE WITH RADIUS END

TREE SHAPE WITH POINTED END

FLAME SHAPE BURRS

CONE SHAPE BURR

CONE SHAPE BURR

CONE SHAPE WITH RADIUS END

CONE SHAPE WITH POINTED END

INVERTED CONE SHAPE

TAPER WITH FLAT HEAD SHAPE BURR

SEMI-CIRCLE SHAPE BURR

Recessed Arc

CYLINDER SEMI-CIRCLE SHAPE BURR

What is the number of teeth?

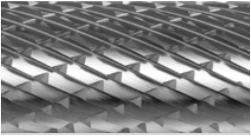

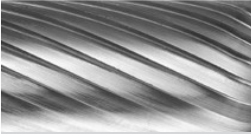

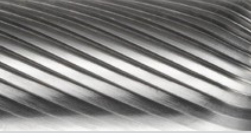

Simply put, the head area of a burr is fixed. If the number of teeth is large, the gap between each tooth will be small, and the whole will be denser (such as CUT 2); otherwise, if the number of teeth is small, the gaps will be large, and the whole will be sparse (such as CUT 3).

– Double cut for general purpose use. Improves control and reduces chips

– Standard cut for general applications

– Fast Mill cut (ALU CUT) for rapid stock removal of softer non-ferrous materials including plastics

– Coarse cut for metal removal and finishing applications on non-ferrous metal alloys

– Fine cut for improved finish on all ferrous metals

– Foundry cut for maximum stock removal, rough edges and foundry applications

– Diamond cut for hardest materials and best finishes

– Chipbreaker cut for fast stock removal. Improves control and surface finish

– Fast Mill cut with chipbreaker for rapid stock removal

SHEN TOOLS can customize the burr with any number of teeth, don’t worry.

Or contact us to see our certificates

Send us a message if you have any questions or request a quote. Our experts will reply you within 24 hours.

Yuyao East Cutting Tools Factory is located in Simen Town, Ningbo City, China. It was established in 1984 and has 40 years of experience in the production of Carbide Cutting Tools. We are a professional manufacturer engaged in the development, manufacture and sales of Carbide Cutting Tools, with two subsidiaries and two sub-brands (Shen Tools & WolfBurrs).

Send us a message if you have any questions or request a quote. We will be back to you ASAP!